Context: Preventing the risk of defects in overhead lines

As they move through cities, tramways are powered by a system of electrified overhead lines and a pantograph, which is a device mounted on the roof of an electric train to transmit power from the overhead line to the tram. Over time, the constant tension between these two elements can degrade the overhead lines or the pantograph itself.

The resulting defects can have a negative impact on rolling stock availability, operational safety and maintenance costs. In Lyon, for example, an average of 10 incidents relating to overhead lines and pantographs occur every year, with the most severe cases leading to network disturbances. In October 2020, a pantograph incident caused a half-day outage on two lines, resulting in €30,000 in maintenance costs, 57 lost rides and a major safety risk.

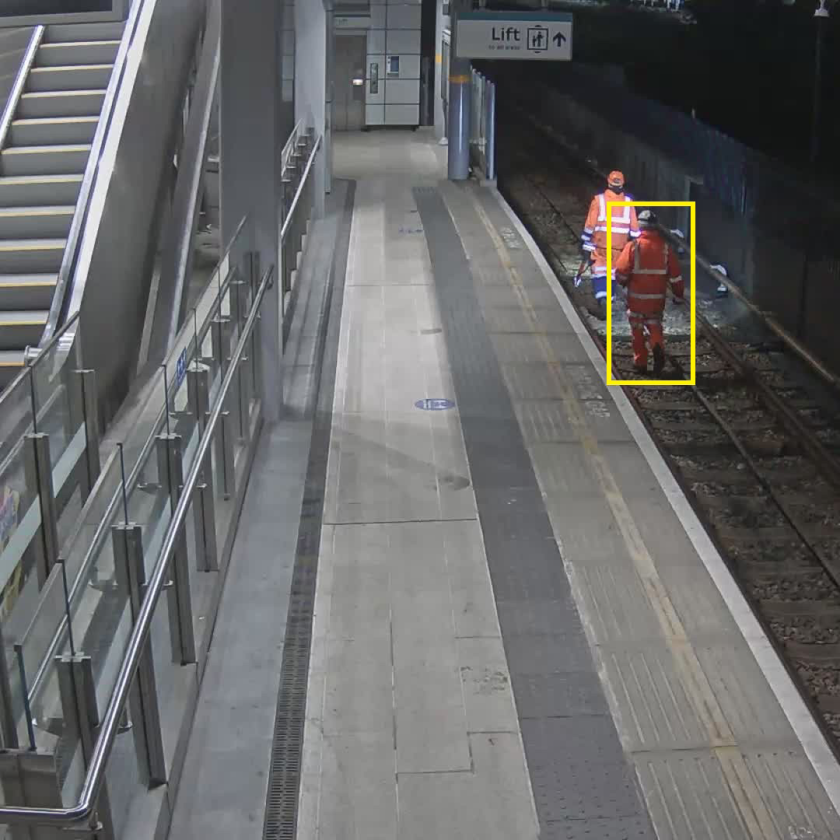

For this reason, preventive maintenance is essential for overhead lines and pantographs on all tramway networks. However, these maintenance operations are made complicated by the fact that they can only be performed by visual inspection on high-tension lines that are located up to 6.5 meters above ground, often in the middle of street traffic.